In CNC Shop, idle time on machines can be up to 25 %. In fact, many CNC Shop Managers even do not know the exact idle time.These firms have bought few costly machines & these are idle for some reason or the other.

What does this mean in terms of production and profitability?

1. Your ROI is straightaway reduced by 25 %.

2. You are maybe producing 75 parts per shift when you could be producing 100.

3. You prices are about 25 % higher, in the cut-throat market out there.

Digitech offer a solution using CIMCO-MDC product. MDC is Manufacturing Data Collection. CIMCO is a Denmark based company.

CIMCO MDC Max

This is the most

advanced module of CIMCO-Denmark for measuring efficiency of a CNC machine in

terms of OEE. This module gives the

on-line display of CNC status. The most important feature is that this gives a

very true data collected from the CNC.

There are 7 different

ways to capture the machine data as below -

1)

Use FOCAS interface in Fanuc : It directly gives data from CNC

Memory

but all FANUC systems do

not

Support this.

2)

Use DPRNT Commands : System puts DPRNT Command in each

Part Program.

e.g. DPRNT [CYCLESTART]

The Cycle Start Signal will be sent

on RS-232 port. But all FAUC do not

support DPRNT function.

3)

Use CIMCO MDC Box : System can take 3 digital signals from

machine via this hardware box on

RS-232 port. Most common signals are

Cycle Start, Cycle Stop & Part

Count

4)

Use Spare Relays in Haas : Haas has Relays like M21, M22 & M23.

These can be wired these to MDC

box.

Further you need to use M codes in

NC Code to activate the relays.

5)

Use Relay Board & Tower Lamp : Take signals from a Tower

Lamp & operate 3

relays.

Use NO contacts of these relays to take

signals to MDC box.

6) Use MTConnect interface : This is a universal protocol developed

recently. Some latest CNC like Mazak,

OKUMA, FANUC, support this.

You can directly get Machine

Status

in MDC by this protocol.

7)

Use NetLINK for Sinumerik 840 : For Sinumerik 840-D, NetLINK

hardware will give most of the MDC

signals.There is a direct interface in

CIMCO-MDC software for NetLINK.

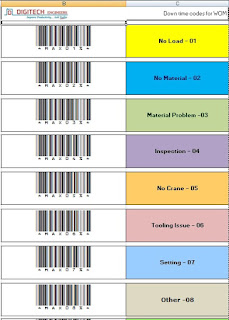

Down time can be scanned by Android cell phone or Tab.

The live OEE will be shown on the Android cell phone. When a machine is under breakdown the system will send the SMS to predefined Cell Number.

For more information, contact digitechpune@gmail.com

You can watch video here https://www.youtube.com/watch?v=-jehAgyrEjM